Engineered enclosure systems

for design-led architecture

Deliver high-performance envelopes without constraining design intent. Quantum Panels help you move faster, coordinate better, and reduce site risk—on new builds, additions, and retrofits.

The Architect’s Headache, Addressed

Projects slip when junctions hide risk and field fixes outnumber the details. Quantum reduces the unknowns:

WHY LEADING ARCHITECTS CHOOSEQuantum PANELS

Engineered panels that perform—without constraining design intent.

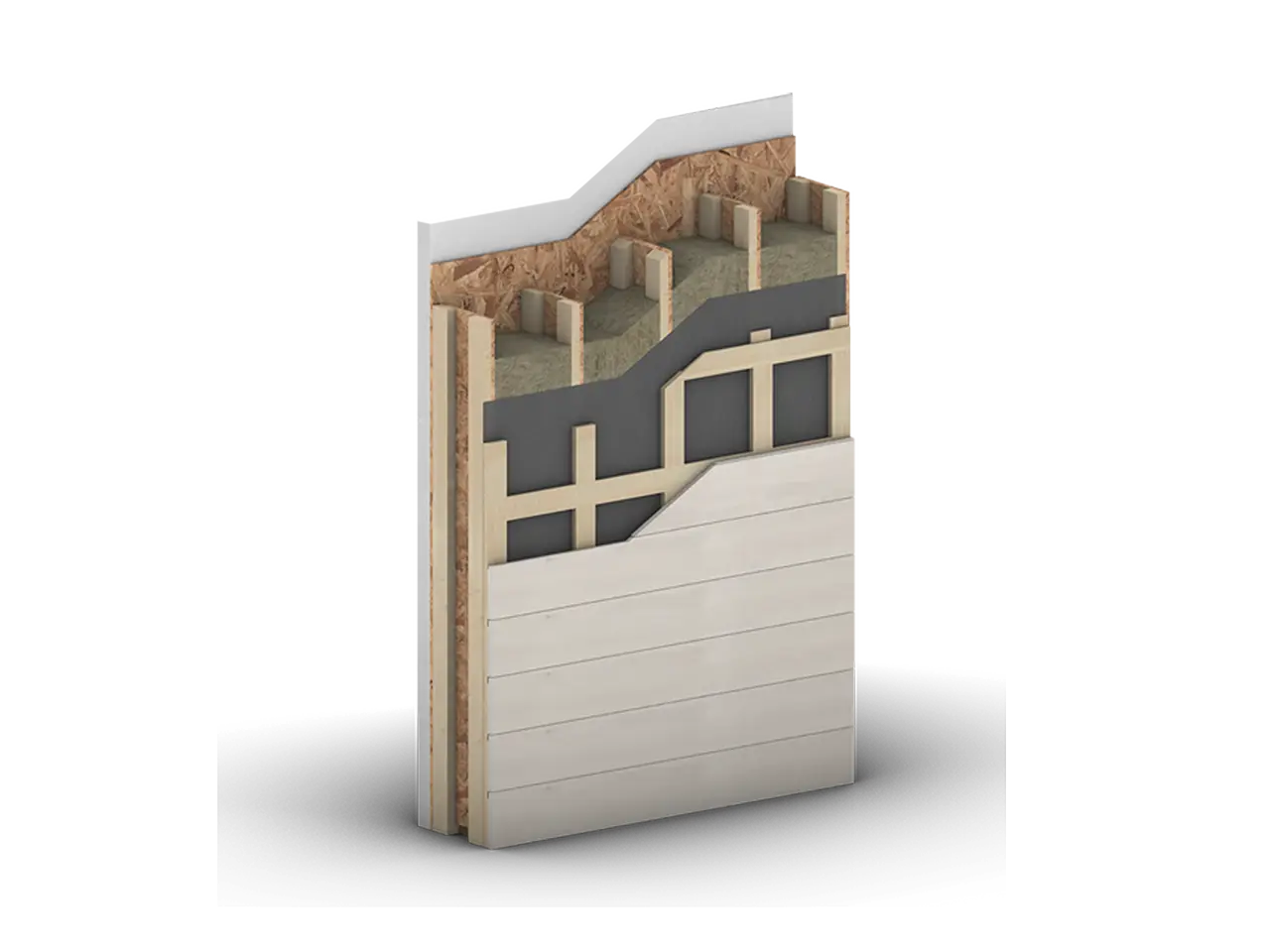

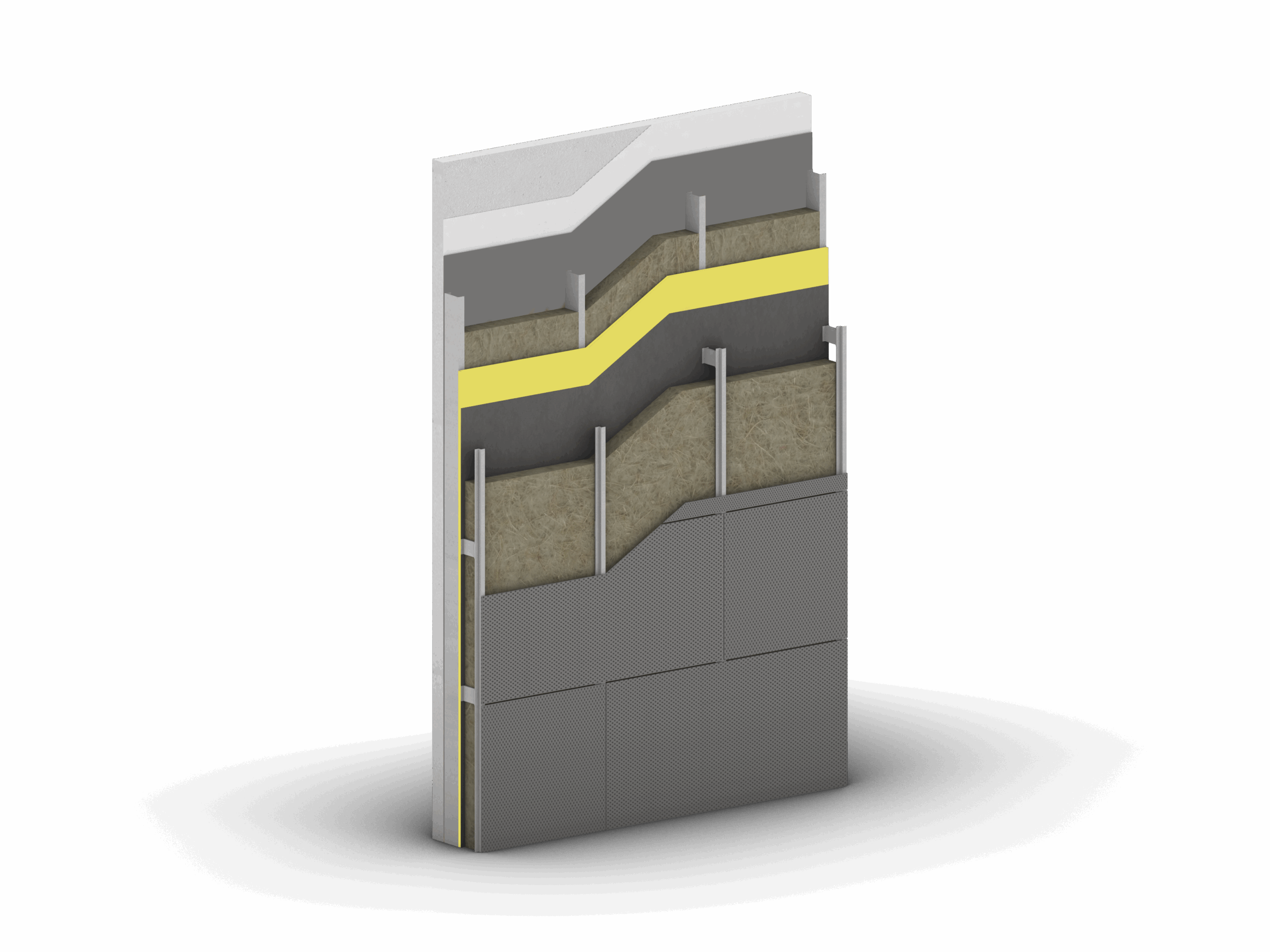

Our modular enclosure system (walls, roofs, and floors) pairs standardized junction details with flexible rainscreen attachment to help you deliver high-performance, code- and Passive House–ready buildings with predictable coordination.

Airtight, thermal-bridge minimized, comfortable by design.

Assemblies achieve up to R-61 (panel-dependent) with warm interior surface temperatures—lower heating/cooling loads and fewer cold-spot complaints.

HOW WE SERVE ARCHITECTS

Design More with Less Complexity.

Standard Revit families/IFC blocks and vetted high-performance details speed up detailing.

Factory precision and coordinated shop drawings minimize field coordination and admin time.

Certified component data mapped to PHPP; assemblies routinely meet or exceed energy-code requirements.

Standardized families align with our panel system and include type parameters, schedules, and keyed notes.

Passive House Institute component certificates with verified Ψ/U values; junction details designed to minimize thermal bridging.

Envelope reviews, clash sets, and stamped shop drawings for Canadian projects—available for new builds, additions, and retrofits.

Engineered assemblies with weather-resistant, vapour-diffusive membranes; Passive House–ready without prescribing exterior cladding.

Predictable Passive House Performance. Stronger Reputation.

Certified Passive House component data with PHPP inputs.

Factory precision and standardized junction details reduce RFIs.

Verified U/ψ values and airtightness drive predictable comfort.

Factory-built, panelized building-envelope systems speed approvals and closeout.

High-performance assemblies and clean detailing help façades command higher fees.

Verified U/ψ plus PHPP inputs reduce risk, win trust, and simplify energy modelling.

Shorter installs and fewer site visits lower financing, carrying, and admin costs.

Design More With

Less Complexity.

Pre-engineered, thermal-bridge-free junction library.

PHPP pack with verified U/ψ values.

Factory docs + BIM families mapped to types.

Exterior architectural wall panels deliver airtight, waterproof envelope performance.

Pre-cut service cavities/subframes—trades install without rework.

Stamped shop drawings and code-ready assemblies speed reviews.

Works with any exterior wall cladding system and custom grids.

Get Started

THE ARCHITECT'S

ROADMAP TO to FASTER, SMARTERDESIGN

DESIGN CONSULTATION

PERFORMANCE VALIDATION

SEAMLESS DOCUMENTATION

PREDICTABLE INSTALLATION

Design Smarter.

Deliver Faster.

Excel Further

Ready?